Many of us work in a potentially dangerous environment and constantly expose ourselves to danger. Safety shoes are designed to minimize any injury that may come from exposing your feet to sharp objects, heavy instruments, electricity, or other volatile substances.

No matter where you work, security should always get the most priority, and safety shoes can protect your feet from a wide range of potentially dangerous materials. Depending on the work environment, there are multiple variations of safety shoes available.

What Are Safety Shoes?

No matter what we do in life, safety should always come first. This is especially true if you work in a risky environment. Workers from different environments are required to wear different safety shoes so that no fallen object or harmful substance can accidentally damage their feet.

These specifically designed shoes are known as “Safety shoes” and are compulsory to wear in many risky work environments. The type of safety shoe you’ll need will depend on the environment you work in, and the type of risk you deal with.

Let’s learn about the types safety shoes come in so that you can pick the right pair of shoes that’ll protect your feet from unpleasant consequences. Let’s get started

Safety Shoes: How Many Types Are There

1. Safety toed shoes

Material — Metal or Composite Material

How it works

These heavy-duty shoes are designed with a special, tough covering over the toe area. The covering is hard enough to protect your toes from most impact and compression damages like a heavy object falling over your toes or you tripping and falling.

They are also known as steel-toed shoes because steel is commonly used to reinforce the toe area. Wearing safety toe shoes is a common practice in mills and factories around the globe.

2. Steel insole shoes

Material — Steel and steel alloys

How it works

Those who drive heavy vehicles all day have to press the pedal for a long time and as a result, can develop foot joint issues. These puncture-proof shoes are also a great fit for workplaces such as construction sites, glass factories, and other hazardous environments.

The shoes come with a steel sole inside and don’t provide much space to move around your foot too much. As a result, the chance of developing foot joint issues decreases significantly and your foot stays protected from getting punctured by stray glass, screws, and nails.

3. Metatarsal shoes

Material — Rubber

How it works

These safety shoes are designed to protect the metatarsal bones in your feet. Alongside protecting your toes like the safety-toed shoes, the Metatarsal shoes offer some additional protection, up to where the boot laces go.

Metatarsal shoes are built with multiple layers of metatarsal guard. The goal is to protect your foot from falling or moving objects. These safety shoes are fairly common in big warehouses.

4. Electric hazard shoes

Material — Metal or Composite Material

How it works

Just as the name suggests, the purpose of these safety shoes is to prevent you from getting electrocuted. These shoes achieve this task by providing thick insulation so the electricity can’t pass through the shoes and you can safely work, even with live wires.

These safety shoes are absolutely essential for electricians across the globe. Electric hazard shoes are built with special materials that are highly resistant to electricity. The materials have the approval of the American Society of Testing and Materials (ASTM).

5. Metal instep footwear

Material — Metal

How it works

Metal instep footwear is used to protect your feet when you accidentally step on sharp objects. This is commonly seen in large industrial factories or construction sites, where the risk of a sharp object penetrating your feet is much higher.

Metal instep footwear offers superior protection from objects like nails, glass, blades, or other sharp metal objects.

6. Wellingtons / PVC Boots

Material — High-quality PVC

How it works

These are primarily used to keep your feet from getting wet. Working in cold, wet feet can soon result in serious illness, and wet/slippery shoes can increase the chance of accidents. Also known as wellingtons, these waterproof boots can prevent water absorption and penetration.

These boots are mainly used to work in a damp and waterlogged environment. However, the soft material won’t be able to protect you from falling/tripping damages.

7. Women’s work boots

Material – Composite Material

How it works

Ladies’ work boots are a bit different from men’s boots. Alongside providing quality protection and comfort, these boots also come in style.

There are also options to choose from construction and engineering (steel toe) boots and hospitals and laboratories (white, non-slip) shoes. Some shoes also come with electrostatic discharge (ESD) protection to work safely in volatile and electric environments.

Safety Ranking

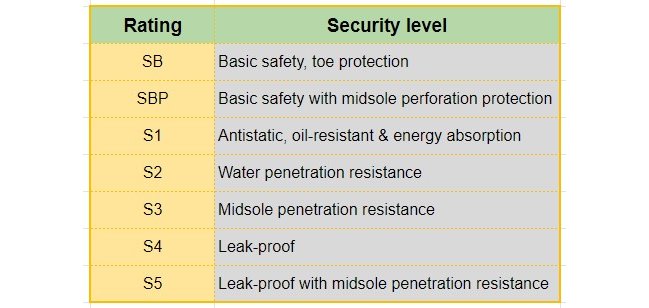

There is also a rating system that can give you a clear picture of the safety we get from safety shoes.

The ranking starts with the letter “S” and is followed by the letter “B” and the numbers 1-5. “SB” means basic level protection and the bigger the number gets, the more secure your safety shoes are.

Here are the rankings of safety shoes around the globe:

What Are Considered Safety Shoes?

For a pair of shoes to be considered “safety shoes”, they have to meet the guidelines from the American Society for Testing and Materials (ASTM). Once certified, each pair is labeled with a set of codes that showcases the level of protection they provide, alongside other info.

The code will look something like this:

ASTM G2413-20

M/I/C

PR

Here, In the first line, the ASTM showcases the certification from the American Society for Testing and Materials (ASTM). The G2413 represents the model number and the 20 represents the safety standard. 20 means that the shoes were made following the 2020 safety standards.

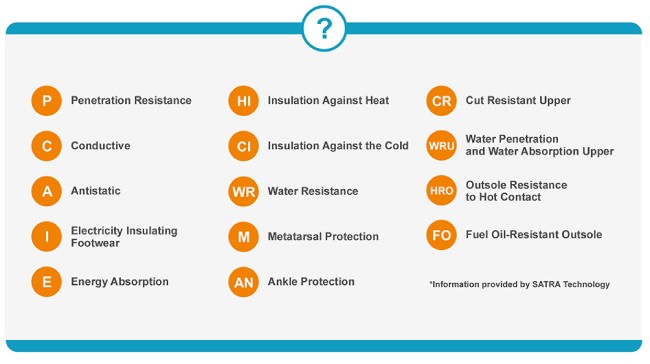

In the next line, the M goes for Men. The I stands for Impact protection and the C represents Compression protection. The third line displays the security levels and there are some definitive abbreviations that you can check out. The list goes like this:

EH – Electrical hazard resistance

PR – Puncture resistance

MT – Metatarsal protection

SD – Static dissipative

CD – Conductive protection

Why are safety shoes important?

As stated earlier, safety always comes first. Workers usually rely on their employer to issue the best protective boots in different work environments. We all want productivity, but not at the expense of workers’ safety. That’s why safety shoes are so important.

According to the Bureau of Labor Statistics, every year, around 60,000 people in the US alone get their feet injured. This number can easily be reduced by using proper safety shoes. If you want to ensure a safe workplace, using and issuing proper safety shoes is a must.

Safety shoes don’t have to be uncomfortable

Contrary to what many people believe, safety shoes don’t have to compromise comfort in order to achieve security. Modern-day safety shoes not only provide adequate security, but they are also comfortable to wear and stylish to look at.

This is true that safety gets the highest priority, but wearing uncomfortable shoes can also create a variety of complications. That’s why most modern manufacturers are taking more and more progressive actions toward comfort and style while keeping safety intact.

Leave a Comment